- +86-156 2426 6857

- amy@sdxxhg.com

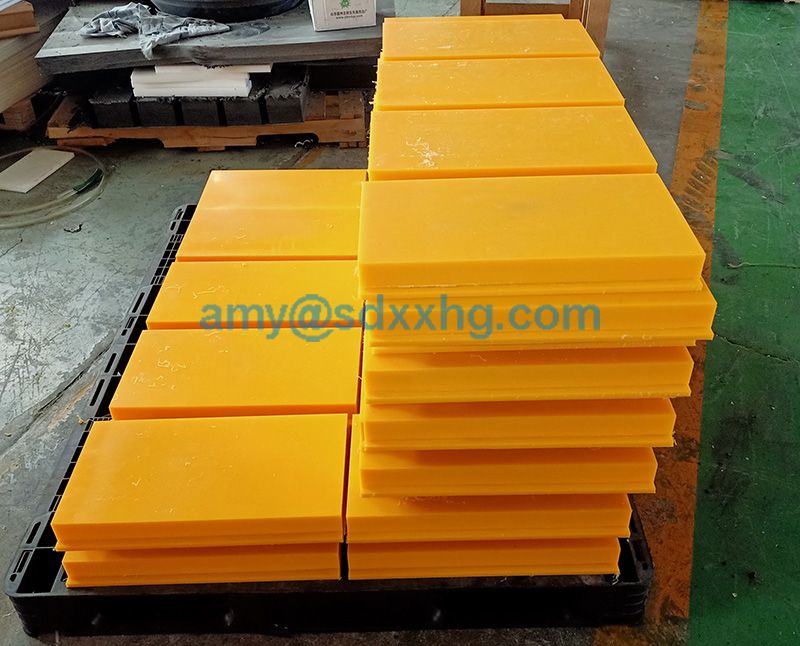

UHMBR SH - Overview

UHMW (Ultra High Molecular Weight Polyethylene) is a common machinable plastic known

for durability, versatility and cost-effectiveness as well as abrasion, impact and chemical resistances.

UHMW plastic features a molecular weight that ranges from 3.1 million to 100 million grams per mole,

with an abrasion resistance that continues to improve as molecular weight increases.

Reprocessed UHMW is an eco-friendly and economical alternative to standard virgin UHMW

that uses a blended version of virgin and recycled UHMW. Reprocessed UHMW is excellent

for non-food applications and offers all the benefits of standard UHMW at a much more

cost effective price. Reprocessed UHMW features the same low coefficient of friction as

standard UHMW while also offering a slightly better wear resistance. Reprocessed UHMW

is used extensively for chain guides, wear rails, chute liners, truck liners, hopper liners and

many other applications where excellent wear properties are required. The standard color

of reprocessed UHMW is black, but also comes in green.

Machinability & Tolerance Warnings:

There is some inherent stresses in the material so if you need tight tolerance parts you may want to

consider a material such as acetal. Standard diameter tolerance of the rods is ±10% This material can

be machined and should not shrink due to the machining process. UHMW expands and contracts

considerably with temperature change. Other materials are available if you need a lower coefficient

of linear thermal expansion. Call our experts at (888) 423-3902 for more information or questions

about what materials to use for your application.

Low Coefficient of Friction

Reprocessed UHMW is used in applications where high levels of friction are likely to arise including

conveyor guard rails, augers and wear strips, belt scrapers, chain guides, and idler rollers. Due to

an extremely low coefficient of friction, its inherent lubricity minimizes heat-generating friction

that tends to gradually destroy steel parts, and ensures smooth, noiseless operation.

Self-Lubricating Formula

High durability, low friction and wear resistance are key reasons why reprocessed UHMW is the

material of choice for a myriad of applications. Reprocessed UHMW offers an extremely low

coefficient of friction due to a specialized built-in lubricant that replaces unwanted grease

and oil. It also enhances efficiency and productivity in many applications. Reprocessed

UHMW's self-lubricating formula helps to extend part life because the internal lubricant

ensures that parts will not break or need replacement.

Features

Odorless, tasteless and nontoxic

Highly resistant to corrosive chemicals (except oxidizing acids)

Extremely low moisture absorption

Very low coefficient of friction

Self-lubricating

Highly resistant to wear and abrasion

Easy to fabricate and machine with common shop and woodworking tools

Reprocessed grades, enhanced bearing and wear grades available, FDA compliant grades available

for greatly extended part life

Reduced maintenance costs and energy consumption

Extends equipment life